49

Years Work experience in manufacturer and exporter of Pastic Bags

Narendra Plastic

Narendra Plastic established in 1975 is India’s leading manufacturer and exporter of plastic bags with an installed capacity to produce over 4.5 billion bags per annum.

Narendra Plastic manufacturing products from plastics like HDPE, LDPE, LLDPE, PP as well as biodegradable plastic, compostable material and PCR material. These products are designed for various end-use applications servicing a large consumer base across various sectors.

Narendra Plastic is today India’s leading manufacturer of plastic bags catering to customers in India and countries across the world. The Government of India has conferred ‘Star Trading House’ status. It has also been awarded India’s ‘Highest Exporter Award’ for this product category for every year since year 1999.

Manufacturing

Manufacturing facilities are located at Daman, about 160 km from Mumbai city and 200 km from Nhava Sheva, India’s largest port. Production units have state-of-the-art technology machinery for production from extrusion process to final product finishing.

Get A Quote-

Manufacturing of stock items and customs products

-

Advanced control systems and processes

-

Custom printing on bags up to six colors

-

Custom packing, labelling and bar-coding

-

Quality control ensure high level of in-process quality control, reduced wastage and optimal product quality.

-

Full equipped testing laboratory

-

Product development and testing

-

Logistics and warehousing– for inward and outward goods

Vision

To drive excellence through Innovative products and services, by continually upgrading technology and processes, that will optimize efficient use of natural resources.

Mission

Envirobag aspires to be the preferred brand in the Plastic industry, striving for sustainable and globally competitive growth while maintaining social responsibility practices.

Our Story

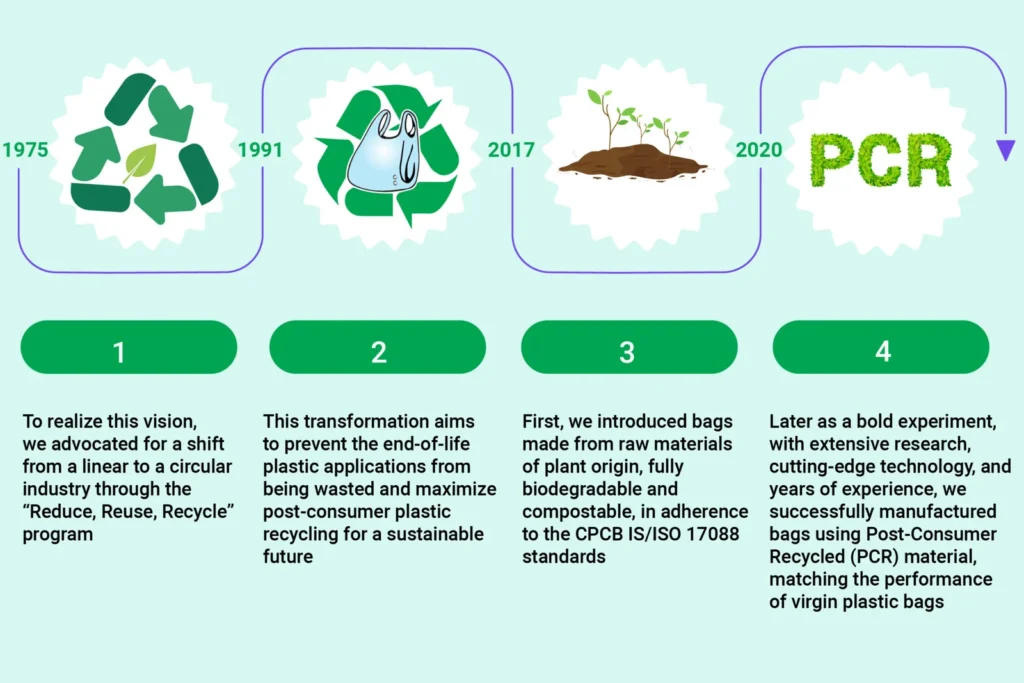

Green Initiative

Narendra subscribes to the 3 R’s program for environmental sustainability.

Narendra Plastic is committed to environmental friendly and sustainability in its operations. We use only prime grade virgin materials that make it possible to reduce material in products for the same performance. Our factory productions processes are fine tuned to reduce waste generation and recycles 100% of plastic waste materials internally. All plastic products manufactured by us are 100% recyclable.

Reduce01

The amount of material used in production

Reuse02

Most of factory waste including oils, solvents, water is reused

Recycle03

100% of plastic waste generated in production is utilised to make recycled material

Meet Our Experts

Team Members

While mirth large of on front. Ye he greater related adapted proceed entered an. Through it examine express promise no. Past add size game cold girl off how old

Jessica Jones

Marketing ExpertJessica Jones

Hello! <br>to the table win-win survival strategies to ensure proactive domination. At the end of the day, going forward, a

Munia Ankor

ArchitectMunia Ankor

Hello! to the table win-win survival strategies to ensure proactive domination. At the end of the day, going forward, a

Ahmed Kamal

Marketing ExpertAhmed Kamal

Hello! to the table win-win survival strategies to ensure proactive domination. At the end of the day, going forward, a

49

Our Testimonials

Plastic bags don’t litter, people do. – Megan Lane, BBC News Published: 2007/11/01

Plastics are lighter than many alternative materials, which translates to a savings in energy use. They have consistently reduced the weight of truck payloads and allowed companies to ship more product in fewer trucks. More than 2.8 million plastic grocery bags can be delivered in one truck.

When incinerated in waste-to-energy facilities, plastic bags yield more energy than coal and burn more cleanly as well.